Lighting is one of the biggest energy spends for large premises businesses, for example food processing plants or manufacturing facilities. Fortunately, it is one of the easiest to address. By upgrading your old lighting to energy efficient LEDs, you could save up to 80% on the energy you use for lighting, and therefore save 80% off that portion of the energy bill.

But lighting is deceitfully complex, especially for large facilities. Many factors need to be taken into account to achieve the correct lighting for the correct environment and use.

So how do you know what that is?

This article will give you an overview of the terminology used for light sources, how their settings apply to your facility, and what standards you should expect. By the end, you’ll understand your needs when it comes to changing the lights in your facilities and what to discuss with any company designing the lighting infrastructure for you.

Glossary of Terms: Light Source

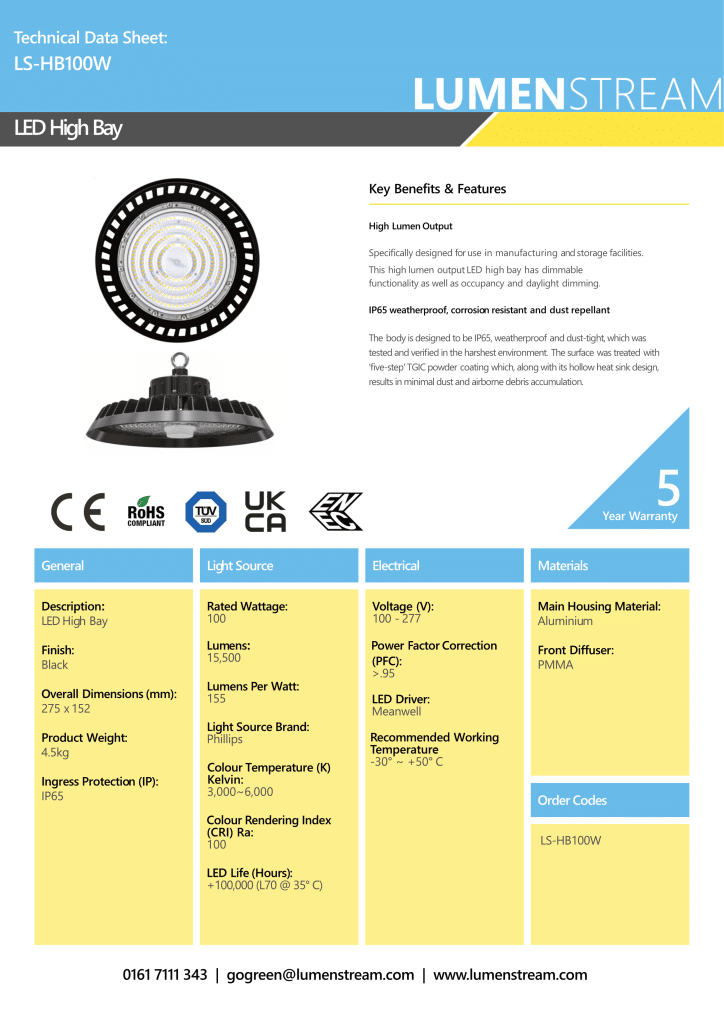

These terms should be found on any Technical Data Sheet on any luminaire proposed to be fitted in your facilities.

Rated Wattage

Rated wattage is the entire energy used to power the luminaire (light fitting) to create light.

Lumens

Where the inspiration for our name comes from, also known as luminous flux. Lumens are the total amount of light that is produced from the light source. If you want to go a little further, the lumen is calculated through the candela (which is not included on a technical data sheet) 1 lumen = 1 candela per steradian. But there’s no need to get too technical!

Lumens per Watt

Or luminous efficacy. This is the important number. The relationship between lumens and wattage is what demonstrates the energy efficiency of the light source. It is essentially how much electrical energy is needed to produce 1 lumen.

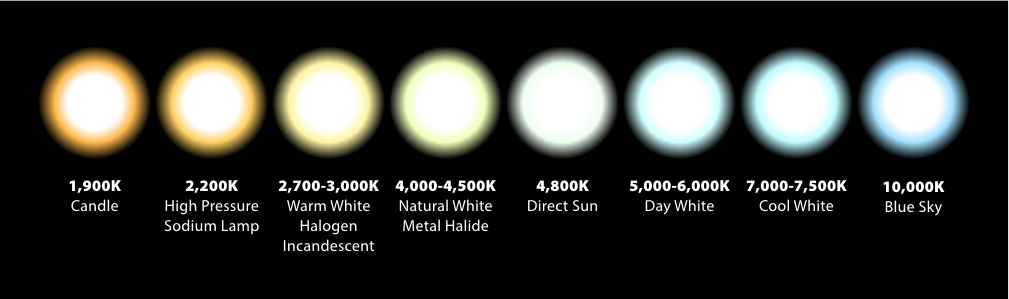

Colour Temperature

Measured in Kelvin (K), colour temperature is the colour of light in its simplest terms.

The lower or ‘cooler’ the colour temperature, the ‘warmer’ the light is. The higher the colour temperature, the ‘cooler’ the light is. It seems counterintuitive but that’s the way it is.

On the spectrum, you could have a colour temperature of 1700K which is red and likened to a match flame. At the other end, you have blue at a colour temperature of 27,000K. See the chart below for a quick glance of Kelvin to what we see.

Colour Rendering Index

(CRI) Ra is used to relay how much an artificial light is close to giving the ‘true colour’ of objects, like that of daylight. The highest CRI is 100 so the closest the light is to 100, the closest it is to providing a true representation of colour. This is critical in spaces where detail like this matters such as product inspection or in big retail stores where you want customers to see your products clearly.

LED Life

Measured in Hours typically, LED life is how long that luminaire is expected to last without repairs under the tested conditions. For example on our Technical Data Sheet for an LED High Bay, you’ll see +100,000 Hours (L70 @ 35℃). This means this High Bay is expected to last roughly 11 years until it starts producing less than 70% of the initial lumen output. In other words, an LED with a label L70 is considered to have reached its end-of-life when it has lost 30% of its lumen output.

Why are these Terms Important?

While it’s important to understand these terms, it is not necessary for you to calculate what you need in your space. We, and other lighting designers, use software called Dialux. DiaLux puts together simulations according to the data we input to calculate the optimum level of lighting and plan for the specific space. We collect this data by completing a detailed survey of your site.

The main reason to know the terminology is so you can check that you are getting the correct level of lighting for your facility and to ensure that you are working with professionals who want to achieve the optimum levels for you.

What You Need to Know

Surprisingly, most places we go into for a survey are not operating under the lighting standards they should be. It is very easy for our eyes to adjust to our surroundings and get used to the light.

Here’s a quick go-to table to understand the levels of lighting you might need for the optimum working environment. They’re taken from CIBSE (the Chartered Institution of Building Services Engineers) but note that it is only a guide and every space should be assessed individually (that’s where Lumenstream comes in).

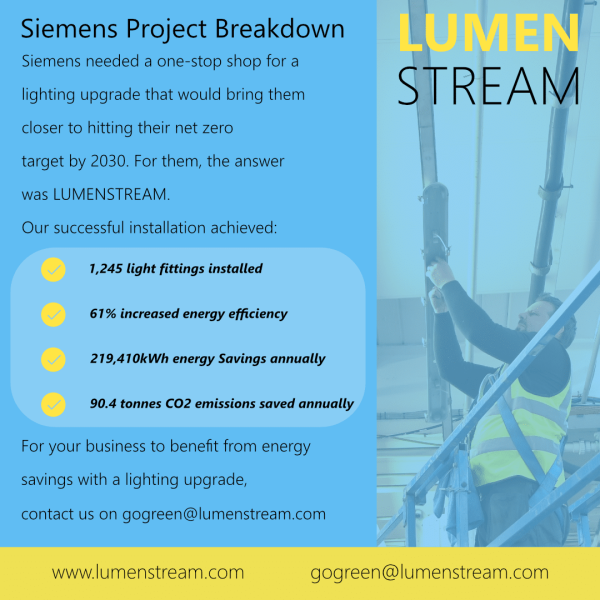

Case Study

Here’s an example of a project we completed with Siemens. It shows the significant energy savings you can make by upgrading your old lighting.

Top Tip

The Society of Light and Lighting published guidance on lighting for facilities managers and costs £30 to download:

The Takeaway

It’s good to know the lighting source terms so you can understand why certain lights are being suggested for different areas of your facility.

Most of all it’s important to know you are getting the optimum lighting levels in any upgrade.

There’s no need to work it all out yourself though, that’s what we do.

To learn more about upgrading your facility to energy efficient LEDs, read our Ultimate Guide to Lighting Upgrades here.